The rapid drumbeat of technological progress demands one thing above all else: speed. From AI accelerators to 5G infrastructure, modern electronics need to process vast amounts of data at blistering speeds, pushing the limits of traditional circuit design. This relentless pursuit of performance has transformed PCB design from a craft into a sophisticated science, requiring Advanced PCB Design Techniques & Methodologies to tame high-frequency signals and ensure unwavering reliability.

It's no longer enough to simply connect components; designers must now meticulously sculpt the electromagnetic environment of their boards. This guide will walk you through the critical challenges, innovative solutions, and essential best practices that define the cutting edge of advanced PCB design and assembly.

At a Glance: Taming High-Speed PCBs

- Signal Integrity is Paramount: Prevent data errors and performance drops by managing signal reflections and crosstalk with techniques like differential signaling and impedance matching.

- Power Must Be Pure: Design robust Power Distribution Networks (PDNs) to deliver clean, stable power to hungry high-speed components, avoiding noise and voltage drops.

- Heat is the Enemy: Implement sophisticated thermal management solutions to dissipate the significant heat generated by compact, powerful devices, preventing degradation and failure.

- Simulate Before You Build: Leverage advanced simulation tools for signal integrity, power integrity, and thermal analysis to catch and fix issues virtually, saving time and money.

- Innovation Extends to Assembly: Modern PCB assembly (PCBA) uses High-Density Interconnects (HDI), flexible materials, advanced packaging, and automated inspection to build more complex and reliable boards.

- Design for Manufacturability (DFM) is Key: Optimize your designs from the start to ensure they can be efficiently and reliably manufactured, reducing rework and increasing yields.

Why Advanced PCB Design Isn't Optional Anymore

Gone are the days when a simple two-layer board and basic routing rules could get the job done for most digital circuits. Today's components operate at gigahertz frequencies, with rise times measured in picoseconds. At these speeds, even a short trace on a PCB behaves less like a simple wire and more like a transmission line. Ignoring this fundamental shift leads to unreliable operation, system crashes, and ultimately, product failure.

The goal isn't just to make a circuit work, but to make it work reliably under diverse conditions, deliver maximum performance, and be cost-effective to manufacture. This requires a deep dive into the physics of electromagnetism, thermodynamics, and material science, integrating them seamlessly into the design process.

Navigating the Core Challenges in High-Speed PCB Design

Designing for high-speed digital circuits introduces a trifecta of complex challenges: maintaining signal integrity, ensuring robust power delivery, and managing thermal loads. Each demands a specialized approach and meticulous attention to detail.

1. Signal Integrity: Keeping Your Data Pure

Signal integrity (SI) refers to the ability of a signal to propagate through a transmission line without distortion, loss, or corruption. In high-speed designs, reflections, crosstalk, and electromagnetic interference (EMI) can severely degrade signal quality, leading to bit errors and system instability.

The Problem:

Imagine shouting into a canyon. The echoes that bounce back distort your original message. In a PCB, signals traveling along traces can "echo" (reflect) when they encounter an impedance mismatch – a sudden change in the electrical properties of their path. These reflections interfere with the original signal, corrupting data. Crosstalk, where a signal on one trace induces noise on an adjacent trace, adds another layer of complexity.

Advanced Solutions:

- Differential Signaling: This technique transmits a signal using two traces with opposite phases (one positive, one negative). The receiver subtracts the negative from the positive, effectively canceling common-mode noise and reflections. It's incredibly robust for high-speed data transmission and is a cornerstone of interfaces like USB 3.0, HDMI, and PCIe.

- Termination Resistors: Strategically placed resistors at the end of transmission lines absorb signal reflections, preventing them from bouncing back and forth. Proper termination, often matched to the trace's characteristic impedance, is crucial for clean signals.

- Advanced PCB Materials: Standard FR4, while cost-effective, can exhibit higher dielectric loss at very high frequencies, attenuating signals. High-speed FR4 variants, ceramic materials, and specialized low-loss laminates (e.g., Rogers, Panasonic Megtron) are designed with stable dielectric constants and low dissipation factors to minimize signal loss and maintain impedance consistency.

- Impedance Matching & Proper Layout: This is fundamental. Traces must be designed with a consistent characteristic impedance (typically 50 ohms for single-ended, 100 ohms for differential pairs) from the driver to the receiver. This involves carefully controlling trace width, dielectric height, and copper pour clearances. Proper layout practices also include minimizing stub lengths, maintaining tight coupling for differential pairs, and separating noisy signals from sensitive ones.

2. Power Delivery (Power Integrity): Fueling Performance

High-speed digital components, especially processors and FPGAs, draw significant and often rapidly changing currents. Ensuring a stable, clean power supply at all times is critical for their operation. Power integrity (PI) focuses on maintaining consistent voltage levels across the entire board, minimizing noise and voltage ripple.

The Problem:

Imagine a city where the power grid can't keep up with demand during peak hours, causing brownouts or surges. Similarly, if a PCB's Power Distribution Network (PDN) can't supply current quickly enough, or if it has too much inductance, the voltage at the component pins can drop (ground bounce/power rail collapse) or fluctuate wildly. This can lead to logic errors, clock jitter, and system instability.

Advanced Solutions:

- Efficient Power Distribution Networks (PDNs): A well-designed PDN acts like a robust power grid for your PCB. It involves multiple layers dedicated to power and ground, strategically placed decoupling capacitors (a mix of high-frequency and bulk capacitors), and wide power planes to minimize impedance and inductance. The goal is to provide a low-impedance path for current surges and absorb noise.

- Power Integrity Analysis and Simulation Tools: Before committing to fabrication, engineers use sophisticated software to simulate the PDN's performance. These tools can identify voltage drops, current densities, and resonant frequencies, allowing designers to optimize capacitor placement, plane shapes, and via structures for optimal power delivery.

- Optimization for Efficiency and Reliability: Beyond raw power, the PDN must be efficient. This means minimizing power loss due to resistance in traces and vias. Careful component selection (e.g., low-ESR capacitors), optimized layout, and thermal considerations (as power loss generates heat) all contribute to a reliable and efficient power delivery system.

3. Thermal Management: Keeping Your Cool Under Pressure

As devices become more compact and powerful, they generate more heat in a smaller area. Unchecked heat can degrade component performance, reduce lifespan, and even lead to catastrophic failure. Effective thermal management is therefore not an afterthought, but an integral part of advanced PCB design.

The Problem:

Think of a powerful computer without proper ventilation; it quickly overheats and throttles performance or shuts down. On a PCB, localized hotspots can create uneven thermal stress, leading to solder joint fatigue or component damage. High temperatures also increase signal noise and reduce the efficiency of power delivery.

Advanced Solutions:

- Incorporating Heat Sinks, Fans, and Thermal Interfaces: These are the frontline defenders against heat. Heat sinks increase the surface area for convective cooling, fans actively move air, and Thermal Interface Materials (TIMs) like thermal paste or pads ensure efficient heat transfer from hot components to heat sinks.

- Optimizing Systems with Advanced Simulation Tools and Thermal Analysis Software: Just like with SI and PI, thermal simulation is indispensable. These tools can model heat flow, identify hotspots, and predict component temperatures under various operating conditions. This allows designers to optimize heat sink size, fan placement, and even copper pour distribution to act as a thermal plane, preventing performance degradation and outright failure. Strategically placing thermal vias (vias filled with conductive material) under hot components can efficiently transfer heat to internal copper planes or to the opposite side of the board for better dissipation.

Design Optimization: The Power of Virtual Prototyping

One of the most significant advancements in modern PCB design methodologies is the widespread adoption of comprehensive simulation and analysis tools. Relying solely on physical prototypes for testing is prohibitively expensive and time-consuming.

By using advanced simulation tools and analysis software for signal integrity, power integrity, and thermal management before manufacturing, engineers can:

- Identify Issues Early: Catch potential signal reflections, voltage drops, or hotspots in the virtual realm.

- Optimize Designs: Iterate on component placement, trace routing, and material selection to achieve desired performance metrics.

- Reduce Costs: Avoid costly re-spins of physical prototypes.

- Enhance Reliability: Ensure the board will perform as expected under real-world conditions.

This shift towards virtual prototyping is critical for developing high-performance, reliable, and cost-effective PCBs. For those looking to dive deeper into the tools that make this possible, explore Your guide to PCB layout software which often includes these powerful simulation capabilities.

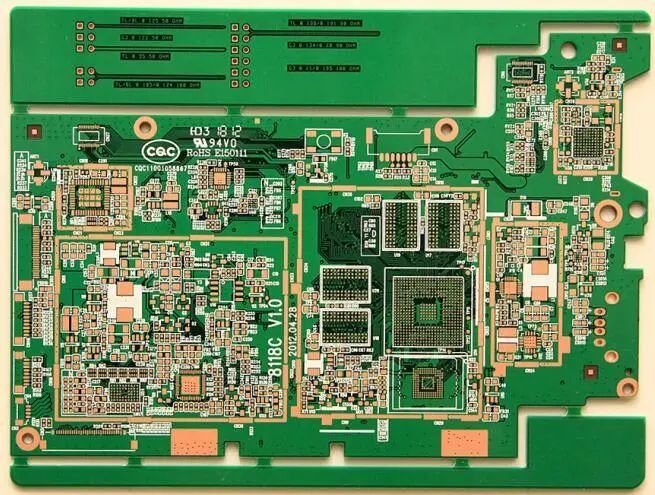

Beyond Design: Innovations in Advanced PCB Assembly (PCBA)

Even the most impeccably designed PCB needs to be manufactured and assembled with precision. The world of PCB Assembly (PCBA) has seen its own revolution, evolving to meet the demands of advanced designs.

The Evolution of PCBA

Assembly has come a long way from its Through-Hole Technology (THT) origins, where components were inserted through holes and soldered on the other side. Surface Mount Technology (SMT), standard since the 1980s, revolutionized PCBA by allowing components to be mounted directly onto the PCB surface. This enabled higher component density, faster automated assembly, and improved electrical performance due to shorter lead lengths. Modern PCBA continues to push boundaries, addressing challenges posed by high-density interconnects (HDI), flexible/rigid-flex PCBs, and advanced packaging techniques.

Key Innovations Driving Modern PCBA

- High-Density Interconnects (HDI): These PCBs achieve significantly higher component density and finer trace widths, allowing for more compact and complex designs. HDI boards utilize microvias (very small vias), blind vias (connecting outer layers to internal layers), and buried vias (connecting internal layers only). These techniques improve signal integrity by reducing stub lengths and minimize PCB size and weight, critical for mobile and wearable devices.

- Flexible and Rigid-Flex PCBs: As the name suggests, these PCBs incorporate flexible materials (often polyimide) or combine rigid and flexible sections. They are ideal for applications with limited space, odd form factors, or those subjected to mechanical stress and repeated flexing. They reduce space requirements, improve reliability by eliminating connectors, and enhance design flexibility.

- Advanced Packaging Technologies:

- System-in-Package (SiP): Integrates multiple components (e.g., processor, memory, sensors) into a single package, reducing overall PCB size and shortening electrical paths for improved performance.

- Chip-on-Board (CoB): Involves directly mounting bare semiconductor chips onto the PCB and then encapsulating them. This method further reduces space, improves electrical performance due to minimal parasitics, and enhances thermal management.

- Automated Optical Inspection (AOI): A critical quality control step, AOI systems use high-resolution cameras and sophisticated image processing algorithms to quickly inspect PCBs for a wide range of defects. This includes missing components, incorrect component placement, misaligned solder joints, and solder bridges, ensuring high-speed and accurate quality control.

- 3D Printing & Additive Manufacturing: While not yet mainstream for mass production of finished PCBs, 3D printing is rapidly gaining traction for rapid prototyping of custom jigs, fixtures, and even specialized low-volume PCBs. This offers unparalleled customization and cost-effectiveness for niche applications and R&D.

Mastering Advanced Assembly Techniques

Beyond the innovations in PCB types and inspection, the physical assembly process itself has evolved to meet the stringent demands of high-speed designs.

- Precision Solder Paste Printing: For fine-pitch components (where pins are very close together), standard stencils aren't precise enough. Advanced stencil designs, such as step stencils (with varying thickness) or electroformed stencils, allow for accurate and consistent solder paste deposition on even the smallest pads. This minimizes defects like solder bridges and insufficient solder.

- Reflow Soldering with Advanced Control: Modern reflow ovens offer extremely precise temperature profiles, crucial for multi-component boards with varying thermal tolerances. Many also use nitrogen atmospheres during reflow to reduce oxidation, leading to stronger, shinier, and more reliable solder joints.

- Selective Soldering: For PCBs that mix Surface Mount Technology (SMT) and Through-Hole Technology (THT) components, selective soldering is often employed. This technique applies solder only to specific areas for THT components, reducing the risk of thermal damage to nearby SMT parts and improving consistency compared to traditional wave soldering.

- Conformal Coating: Once assembled, many high-reliability PCBs receive a conformal coating – a thin, protective polymer layer. This shields the board and its components from environmental factors like moisture, dust, chemicals, and extreme temperatures, ensuring uniform coverage and long-term reliability in harsh conditions.

- Advanced Testing & Inspection: Quality assurance goes beyond AOI.

- X-ray Inspection: For components like Ball Grid Arrays (BGAs) where solder joints are hidden underneath the package, X-ray inspection is essential to detect hidden defects like voids, shorts, or misalignments.

- In-Circuit Testing (ICT): This method uses a "bed of nails" fixture to make contact with test points on the board, verifying the functionality of individual components and circuits, checking for shorts, opens, and correct component values. This comprehensive testing ensures the quality and reliability of the assembled board.

Best Practices for Flawless High-Speed PCBs

Even with the most advanced tools and techniques, success hinges on adopting a disciplined, forward-thinking approach.

- Design for Manufacturability (DFM): This is perhaps the most critical best practice. DFM means optimizing your design from the very beginning for ease of manufacturing and assembly. This includes sensible component placement for pick-and-place machines, appropriate pad sizes for reliable soldering, clearances between traces and components, and proper via structures. Integrating DFM early in the design cycle significantly reduces manufacturing defects, rework, and overall costs, leading to higher yields.

- Material Selection Matters: The choice of PCB substrate, solder paste, and conformal coating must align with the operational environment and performance requirements. Factors like dielectric constant (Dk), dissipation factor (Df), thermal conductivity, and coefficient of thermal expansion (CTE) are paramount for high-speed, high-power designs. Understanding these properties ensures signal integrity, thermal stability, and long-term reliability.

- Process Control & Monitoring: Implementing real-time monitoring and Statistical Process Control (SPC) for critical parameters throughout the assembly line is essential. This includes meticulously tracking temperature profiles in reflow ovens, humidity levels in solder paste storage, and solder paste viscosity. Proactive monitoring helps identify and correct deviations before they lead to widespread defects.

- Training & Skill Development: Advanced PCBs require advanced skills. Ongoing training for the workforce in new technologies, assembly techniques, and quality control procedures is non-negotiable. A skilled and knowledgeable team is the backbone of high-quality advanced PCBA.

- Continuous Improvement: The PCB landscape is constantly evolving. Regular process audits, adopting lean manufacturing principles to eliminate waste, and fostering a culture of innovation are vital. Continuously seeking ways to optimize efficiency, enhance quality, and improve reliability ensures that your advanced PCB designs remain competitive and perform at their peak.

Common Questions & Misconceptions About Advanced PCB Design

Q: Is 3D printing a viable option for manufacturing complex, high-speed PCBs in production?

A: Currently, 3D printing (or additive manufacturing) for PCBs is primarily used for rapid prototyping, specialized jigs, fixtures, and very low-volume custom applications. While the technology is advancing rapidly, it's not yet ready for mass production of high-speed, multi-layer PCBs with the required electrical performance and reliability of traditional subtractive manufacturing methods. The resolution, material properties (especially dielectric performance), and cost-effectiveness for large volumes are still hurdles.

Q: Do I really need expensive low-loss materials for every high-speed design?

A: Not necessarily for every design, but it depends on the signal frequencies, trace lengths, and performance requirements. For moderately high speeds or shorter traces, a well-designed FR4 board with careful impedance control can be sufficient. However, as frequencies push into the multi-gigahertz range or trace lengths increase, the dielectric losses in standard FR4 become significant. At that point, investing in low-loss materials (like certain high-speed FR4 variants or exotic laminates) is crucial to maintain signal integrity and avoid excessive attenuation. Simulation tools can help determine the tipping point.

Q: Can I just add more decoupling capacitors to solve power integrity issues?

A: While decoupling capacitors are fundamental to power integrity, simply adding "more" isn't a magic bullet. Their placement, value, type (e.g., ceramic, tantalum), and connection to the power and ground planes are all critical. A poorly placed capacitor can be ineffective. More importantly, a holistic PDN design, including wide power planes and understanding the target impedance of the PDN, is far more effective than an indiscriminate scattering of capacitors. Simulation tools are essential for optimizing capacitor networks.

Your Next Steps in Advanced PCB Design

The journey into advanced PCB design is continuous, marked by constant learning and adaptation. As components become faster and more integrated, the demands on your design methodologies will only increase.

To truly excel, consider these actionable steps:

- Deepen Your Knowledge of Electromagnetism: Understand transmission line theory, skin effect, and dielectric loss. These aren't just academic concepts; they are the bedrock of high-speed design.

- Master Simulation Tools: Invest time in learning and utilizing SI, PI, and thermal simulation software. Treat these as essential design tools, not just validation steps.

- Embrace DFM: Integrate Design for Manufacturability principles into every stage of your design process. Collaborate closely with manufacturers to understand their capabilities and limitations.

- Stay Current with Material Science: Keep an eye on new PCB substrate materials and their performance characteristics. The right material can often simplify a complex electrical problem.

- Network and Learn from Peers: Engage with other experienced designers, attend industry conferences, and participate in online forums. The collective wisdom of the community is invaluable.

By embracing these advanced techniques and methodologies, you're not just designing PCBs; you're engineering the very backbone of tomorrow's high-performance electronics.