In today's fast-paced electronics industry, the days of isolated "black box" design and manufacturing processes are long gone. Building cutting-edge printed circuit boards (PCBs) – those tiny, intricate brains behind nearly every modern device – demands more than just brilliant individual engineers and state-of-the-art machinery. It requires a seamlessly connected web of PCB software integrations & ecosystems that transforms disjointed workflows into a symphony of efficiency, accuracy, and innovation.

This isn't about simply having good software; it's about making that software talk to each other, creating a transparent, "white box" environment where design intent flows unimpeded from concept to final product. Without robust integrations, even the most sophisticated tools become bottlenecks, leading to costly errors, delays, and missed opportunities.

At a Glance: Why Integrated PCB Software Matters

- Breaks Down Silos: Connects design, manufacturing, and test data for a holistic view.

- Boosts Accuracy: Reduces manual data entry errors and ensures consistency across stages.

- Accelerates Time to Market: Streamlines workflows, identifying issues earlier and faster.

- Enhances Collaboration: Fosters better communication between designers, manufacturers, and test engineers.

- Improves Quality & Reliability: Enforces design for manufacturing (DFM) and assembly (DFMA) rules.

- Maximizes ROI: Lowers design costs and increases overall development efficiency.

- Provides Real-time Visibility: Offers instant insights into production status and performance.

Beyond the Black Box: The Industry's Shift to Seamless Connectivity

For years, the electronics design and manufacturing landscape often resembled a series of isolated islands. Designers would craft their creations using specialized Electronic Design Automation (EDA) tools, then metaphorically toss their files "over the wall" to manufacturing. Production teams would then interpret these designs, often making assumptions or encountering unforeseen challenges that required extensive back-and-forth. Testing, the final hurdle, would then operate largely independently, simply verifying the outcome.

This "black box" approach was fraught with inefficiencies. Data transfer was often manual, prone to errors, and lacked context. Design intent, crucial for a smooth build, could easily be lost in translation. As devices became smaller, faster, and exponentially more complex, this disjointed model became unsustainable.

Enter the "white box" approach, championed by industry leaders like EMA Design Automation. This philosophy emphasizes transparency and open communication across the entire product lifecycle. It means contract manufacturers (CMs) are involved earlier, their design for manufacturing and assembly (DFMA) rules are considered upfront by PCB designers, and crucially, CMs truly understand the original design intent.

The PCB design process, encompassing schematic capture and PCB layout, is the foundational stage, dictating how a board will be built and what tests it will undergo. Therefore, integrating design tools with downstream manufacturing and test systems isn't just a nicety; it's the bedrock of modern electronics development. Smart integrations significantly improve the effectiveness and efficiency of this entire workflow, ensuring greater accuracy, data transfer security, and ultimately, design quality.

The True Cost of Disconnection: Why Siloed Software Fails

Imagine trying to build a complex machine where each department uses different blueprints, speaks different languages, and rarely communicates. That's essentially the challenge posed by siloed PCB software. The consequences are far-reaching:

- Data Inconsistencies: Information gets re-entered manually, leading to typos, outdated versions, and conflicting data points between design files, bill of materials (BOMs), and manufacturing instructions.

- Delayed Time to Market: Each disconnect introduces a potential pause. Revisions, clarification requests, and rework cycles extend development timelines considerably.

- Increased Rework & Scrap: When design flaws aren't caught early due to a lack of DFM feedback, costly manufacturing errors result in scrapped boards or expensive rework.

- Limited Traceability: Pinpointing the root cause of an issue in a finished product becomes incredibly difficult without a clear digital thread connecting design, component sourcing, manufacturing steps, and test results.

- Reduced Innovation: Engineers spend valuable time on administrative tasks and debugging communication breakdowns instead of focusing on novel solutions and product enhancements.

- Security Risks: Manual data transfers or reliance on generic file formats can create vulnerabilities, especially when dealing with proprietary designs.

Optimizing the flow of data between all software tools throughout the PCB design process isn't just about incremental gains; it's about achieving quantum leaps in efficiency and accuracy, minimizing product design cost, and maximizing development ROI.

Unpacking the PCB Software Ecosystem: Your Digital Toolbelt

A truly integrated PCB software ecosystem comprises several key categories of tools that work in concert. Understanding each component and how they interact is crucial for building a cohesive system.

1. Design & Analysis Tools (EDA)

These are the fundamental tools for bringing a circuit board to life. They include:

- Schematic Capture Software: Where the electrical design is first drawn, defining components and their connections.

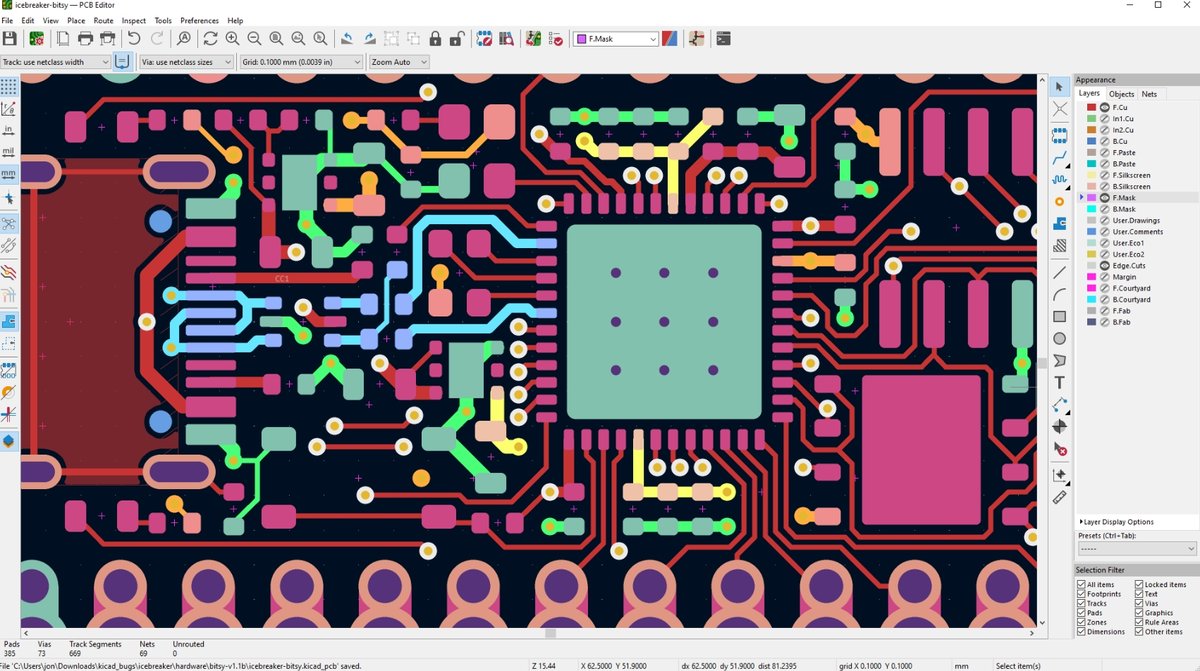

- PCB Layout Software: This is where the virtual board comes to life. Here, components are placed, traces are routed, and the physical characteristics of the board are defined. When considering these tools, you'll want to explore PCB layout software that offers robust design rule checking (DRC) and integrates seamlessly with other stages.

- Simulation & Analysis Software: Tools for predicting electrical performance, thermal behavior, signal integrity, and power integrity before physical prototypes are made. This is critical for catching issues early.

- Mechanical CAD (MCAD) Integration: Ensuring the PCB fits perfectly within its enclosure, often involving 3D model exchange.

EMA Design Automation specializes in providing these kinds of advanced PCB design and analysis packages, understanding that the foundational design work informs and dictates everything downstream.

2. Manufacturing Execution Systems (MES)

This is where the rubber meets the road – or rather, where the digital design meets the physical factory floor. An MES acts as the digital nervous system for your production operations, translating design data into actionable manufacturing instructions and capturing real-time feedback.

SMC, with over 20 years of experience in the PCB industry, highlights the critical role of robust MES solutions. Their capabilities, which include L-M-H Volume, Complex PCBA, ICT, FCT, and RF testing, are underpinned by state-of-the-art software like the Aegis Manufacturing Execution System.

The Aegis MES, designed specifically for the Electronics Industry, exemplifies what a powerful integration looks like:

- Unique Routing Enforcement: It provides and enforces unique routing through manufacturing by assembly and revision, ensuring every board follows the correct sequence of operations.

- ERP BOM & CAD Integration: It integrates the Enterprise Resource Planning (ERP) Bill of Materials (BOM) with the customer's CAD data into a centralized database, eliminating discrepancies and ensuring everyone works from the same, most current component list and design.

- Electronic Work Instructions: Supports unique operator IDs with defined roles and rights, delivering electronic work instructions tailored to each routing point, assembly, and revision. This ensures operators have accurate, visual guidance at their fingertips.

- Serialized Tracking: Assigns unique serial numbers to each assembly and creates parent/child relationships for final assemblies and sub-assemblies. This provides unparalleled traceability from individual components to the complete product.

- Test Data Capture: Stores test results and data directly from automated testers, linking them to specific serial numbers. This is invaluable for quality control, root cause analysis, and compliance.

- Tooling Management: Tracks required tooling by serialized number, ensuring the right tools are available and calibrated for each job.

- Hyperlinked Instructions: Supports hyperlinked work instructions or external programs for operators, providing access to additional resources, videos, or detailed specifications as needed.

This level of integration transforms manufacturing from a series of disconnected steps into a highly controlled, traceable, and efficient process.

3. Enterprise Resource Planning (ERP) Systems

ERP software manages the core business processes: inventory, procurement, supply chain, finance, and human resources. For PCB manufacturing, the crucial integration point is the Bill of Materials (BOM) and inventory management. An integrated ERP ensures that the components specified in the design are correctly ordered, tracked, and available when needed, avoiding costly production delays due to part shortages.

4. Product Lifecycle Management (PLM) Systems

PLM systems manage a product's entire journey from conception to end-of-life. For PCB development, this means managing design versions, change orders, documentation, and stakeholder collaboration. PLM acts as the central repository for all product-related data, ensuring everyone has access to the latest approved files and a complete history of changes.

5. Test & Measurement Software

After manufacturing, boards undergo rigorous testing. This can include:

- In-Circuit Test (ICT): Verifies the integrity of the bare board and component placement.

- Functional Test (FCT): Checks if the board performs its intended electrical functions.

- Radio Frequency (RF) Test: Essential for boards operating at high frequencies.

Integrating test software with the MES and design data allows for automated test program generation, direct capture of test results linked to specific board serial numbers, and real-time analysis of test yields. This feedback loop is vital for identifying and correcting design or manufacturing issues quickly.

How Smart Integrations Elevate Your Workflow: Tangible Benefits

Bringing these disparate software systems together isn't just about neatness; it unlocks significant advantages across the entire product development lifecycle.

Enhanced Design for Manufacturability (DFM) & Assembly (DFMA)

One of the most profound benefits of integration is the ability to bake manufacturing considerations into the design process itself. EMA Design Automation emphasizes that smart integrations allow PCB designers to directly incorporate contract manufacturer (CM) DFMA rules. Instead of finding out during production that a component is too close to an edge or a trace is too narrow for efficient soldering, these issues are flagged during layout. This proactive approach saves immense time and cost associated with late-stage design changes and rework.

Streamlined Data Transfer & Accuracy

Manual data transfer is the enemy of accuracy and efficiency. Each time data is manually re-entered or converted, there's a risk of error. Integrated systems automate this process, ensuring that the BOM from your design tool seamlessly populates your ERP, and design layouts are directly consumable by the MES. This continuous digital thread minimizes errors, ensures data consistency, and drastically reduces the time spent on validation and reconciliation, leading to greater efficiency and accuracy, and maximizing development ROI.

Real-time Visibility & Control

Imagine knowing the exact status of every PCB on the factory floor, from component kitting to final test. An integrated MES, like SMC's Aegis system, provides this level of real-time visibility. By assigning unique serial numbers and tracking assemblies through each step, the system offers unprecedented insight into production progress, bottlenecks, and quality metrics. This granular control allows for immediate intervention, optimized resource allocation, and predictable delivery schedules.

Accelerated Development Cycles

When information flows freely and processes are automated, development cycles naturally shrink. Design iterations are faster because DFM feedback is immediate. Production ramp-up is smoother due to clear instructions and robust data. Testing is more efficient with automated program generation and data capture. This collective acceleration means faster time to market for your products, a critical competitive advantage.

Improved Quality & Compliance

Rigorous quality control and adherence to industry standards are non-negotiable. Integrated systems enforce these standards at every step. From design rule checks in EDA tools to enforced routing and electronic work instructions in an MES, software ensures compliance. Furthermore, the detailed data capture capabilities, like storing test results linked to specific serial numbers (as provided by Aegis), create an irrefutable audit trail, essential for regulatory compliance and product liability. SMC's focus on Lean manufacturing, rigorous quality control, and an outstanding Quality Management System is significantly enhanced by such integrated software.

Navigating the Integration Journey: A Strategic Approach

Implementing a comprehensive PCB software ecosystem isn't an overnight task. It requires strategic planning and a clear understanding of your organizational needs.

1. Assess Your Current State: Identify the "Black Boxes"

Before you can build bridges, you need to know where the chasms are. Conduct an audit of your current PCB design, manufacturing, and test processes.

- Where do manual data transfers occur?

- Which departments struggle with information sharing?

- Where are the recurring errors or bottlenecks?

- Are you currently missing critical traceability data?

Identifying these pain points will help you define the scope and priorities for your integration efforts.

2. Define Your Needs: What Problems Are You Solving?

Don't integrate for integration's sake. Clearly articulate the specific challenges you aim to overcome. Are you trying to:

- Reduce design errors leading to rework?

- Improve manufacturing efficiency?

- Gain better control over your supply chain?

- Accelerate new product introduction?

- Enhance product quality and reliability?

Your answers will guide your technology choices and implementation strategy.

3. Choose the Right Partners & Solutions: Expertise Matters

This isn't a DIY project for most organizations. Partnering with an industry leader that possesses the expertise and experience is often the best option to avoid costly incorrect decisions, as EMA Design Automation rightly advises. Look for vendors who offer:

- Integrated Suites: Solutions designed to work together from the ground up, reducing compatibility headaches.

- Custom Integration Capabilities: The flexibility to connect unique or legacy systems. EMA Design Automation, for instance, provides custom integration software alongside their design and analysis packages.

- Engineering Expertise: A partner who understands both the software and the nuances of PCB design and manufacturing processes. SMC's deep industry experience and QMS approach are examples of this level of expertise.

- Scalability: Solutions that can grow with your business and evolving needs.

4. Phased Implementation: Avoid the "Big Bang"

Trying to integrate every system simultaneously can be overwhelming and risky. A phased approach is generally more successful. Start with the most critical integration points that promise the highest immediate ROI. For example, integrating your EDA tools with your MES might be a strong first step to address DFM issues and streamline data transfer to the factory floor.

5. Custom vs. Off-the-Shelf Integrations: When to Build, When to Buy

Some integrations might be available as standard connectors within commercial software packages. These "off-the-shelf" solutions are often the most cost-effective and quickest to implement. However, if your workflows are highly specialized or you need to connect unique legacy systems, custom integration software might be necessary. This requires more development effort but offers tailored solutions precisely matching your needs. EMA Design Automation, recognizing this, provides both standard packages and custom integration software.

Deep Dive: The Aegis MES as a Backbone for the Factory Floor

Let's take a closer look at how a robust MES like Aegis, as deployed by SMC, functions as a powerful integration hub for the "build" and "test" phases.

Imagine a new PCB design is finalized in your EDA software. Instead of generating static files that a manufacturing engineer then manually interprets, an integrated system pushes this design directly into the Aegis MES. Simultaneously, the ERP system feeds the latest Bill of Materials (BOM) and component availability data.

- Design-to-Manufacturing Translation: Aegis ingests the CAD data and the ERP BOM, reconciling them into a unified, manufacturing-ready format. This ensures that the components specified by design are precisely what the factory is instructed to use.

- Dynamic Work Instructions: Based on the specific assembly and revision, Aegis generates electronic work instructions at each station. These aren't generic; they might include hyperlinked documents, videos, or CAD renderings, ensuring operators have the exact, real-time guidance they need. Crucially, operator IDs with defined roles and rights ensure only authorized personnel perform specific tasks.

- Unique Serialization & Traceability: As each board or sub-assembly enters production, it's assigned a unique serial number. Aegis tracks this serial number through every single process step, recording who did what, when, and with what tooling. If sub-assemblies are integrated, parent/child relationships are established, providing full lineage for the final product.

- Integrated Test Data: When a board moves to an ICT, FCT, or RF test station, the automated testers communicate directly with Aegis. Test results, pass/fail status, and diagnostic data are instantly uploaded and linked to the board's unique serial number. This creates a powerful feedback loop: if a particular batch of boards is failing a specific test, the system can immediately flag earlier manufacturing steps or even component batches for investigation.

- Quality Management & Auditing: All this captured data forms an impenetrable audit trail. From raw materials to design versions, manufacturing processes, and final test results, every piece of information is linked. This is invaluable for quality control, root cause analysis, and demonstrating compliance with rigorous industry standards (which aligns perfectly with SMC's outstanding Quality Management System).

This level of integration is what truly defines a "state-of-the-art software" approach, moving beyond simple automation to intelligent, interconnected manufacturing.

Common Pitfalls to Avoid on Your Integration Journey

Even with the best intentions, integration projects can stumble. Be aware of these common traps:

- Ignoring Legacy Systems: It's tempting to focus only on new, shiny tools. But if critical data or processes reside in older systems, you must plan for their integration or migration. Don't leave them as isolated islands.

- Underestimating Data Migration: Moving data from old systems to new, especially when formats differ, is often more complex and time-consuming than anticipated. Allocate ample resources and time for this crucial step.

- Lack of Stakeholder Buy-in: Without support from all levels – from leadership providing resources to shop floor operators adopting new tools – even the most brilliant integration strategy can fail. Involve key users early and often.

- "Set It and Forget It" Mentality: An ecosystem is dynamic. New software versions, changing business needs, and evolving technologies mean integration isn't a one-time project. It requires ongoing maintenance, updates, and optimization.

- Over-Customization: While custom solutions have their place, excessive customization of off-the-shelf software can create maintenance nightmares and make future upgrades difficult and costly. Always weigh the benefits of customization against the long-term cost.

Your Next Steps in Building a Robust PCB Software Ecosystem

The journey toward a fully integrated PCB software ecosystem is a strategic imperative, not a luxury. It's about empowering your teams, enhancing your products, and securing your competitive edge.

To start, take an honest look at your current processes. Where are the inefficiencies? Where do information gaps create friction and errors? Armed with this understanding, begin researching solutions and, crucially, partners. Lean on the expertise of companies like EMA Design Automation for design and analysis solutions, and look to experienced manufacturers like SMC who leverage advanced MES systems to ensure your designs transition flawlessly to the factory floor.

Remember, the goal isn't just to buy more software; it's to create a seamless digital thread that connects every stage of your PCB development and manufacturing process. By investing in smart PCB software integrations & ecosystems, you're not just improving workflows; you're building a foundation for continuous innovation, superior product quality, and accelerated growth in a demanding market. The future of electronics manufacturing is connected, and your business needs to be too.